Aluminium Extrusion Profiles

Introduction to Aluminium Extrusion Profiles

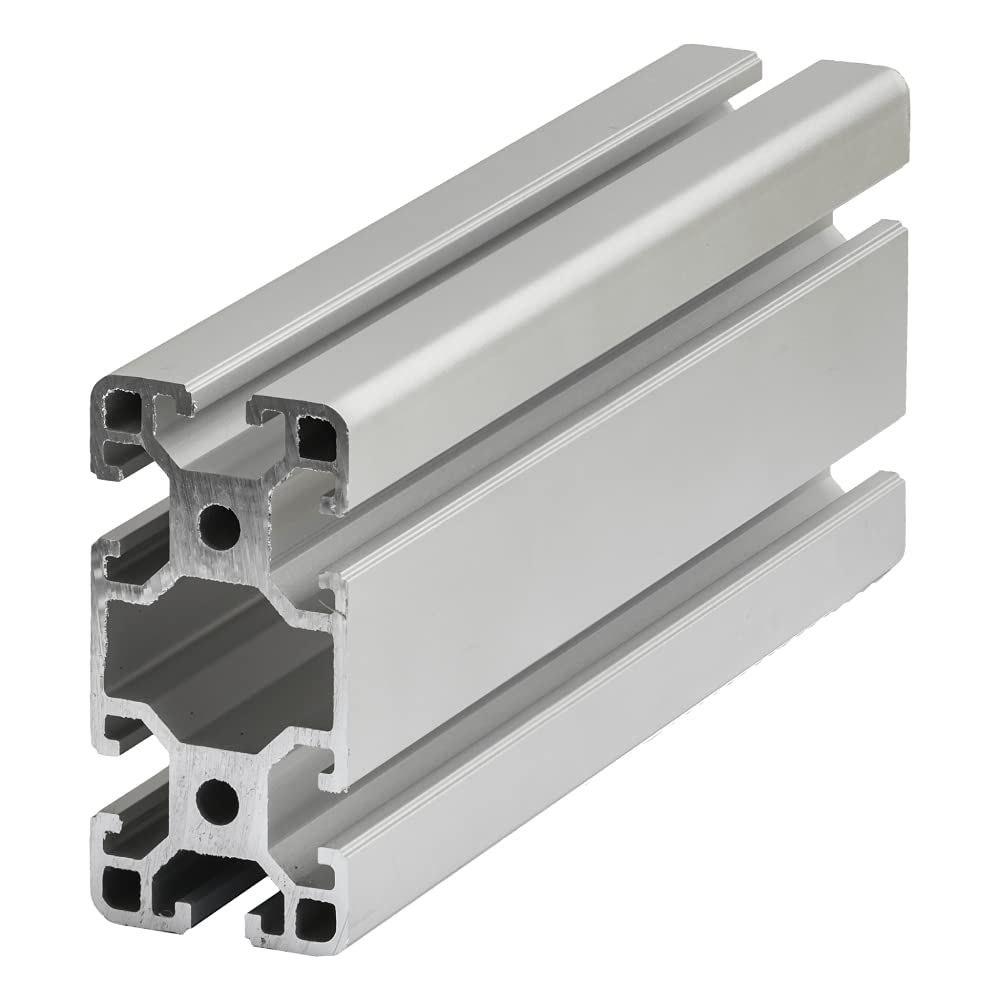

Aluminium extrusion profiles are a type of product that is created through the extrusion process, where aluminium alloy is pushed through a die to create a specific shape and profile. This process allows for the creation of complex and intricate designs, making aluminium extrusion profiles a popular choice for a wide range of applications, including construction, transportation, and industrial manufacturing. The use of aluminium in these profiles provides a number of benefits, including corrosion resistance, high strength-to-weight ratio, and good electrical conductivity.

Benefits of Aluminium Extrusion Profiles

The benefits of using aluminium extrusion profiles are numerous. Some of the key advantages include: * Lightweight: Aluminium is a lightweight metal, making it ideal for applications where weight is a concern. * Corrosion resistant: Aluminium has a natural oxide layer that protects it from corrosion, making it a great choice for use in harsh environments. * High strength-to-weight ratio: Aluminium has a high strength-to-weight ratio, making it suitable for applications where high strength is required. * Good electrical conductivity: Aluminium is a good conductor of electricity, making it a popular choice for electrical applications. * Recyclable: Aluminium is 100% recyclable, making it a sustainable choice for applications where environmental impact is a concern.

Applications of Aluminium Extrusion Profiles

Aluminium extrusion profiles are used in a wide range of applications, including: * Construction: Aluminium extrusion profiles are used in building frames, windows, doors, and other architectural features. * Transportation: Aluminium extrusion profiles are used in the manufacture of vehicles, including cars, trucks, and trains. * Industrial manufacturing: Aluminium extrusion profiles are used in the manufacture of machinery, equipment, and other industrial products. * Electrical applications: Aluminium extrusion profiles are used in the manufacture of electrical components, including wires, cables, and electrical connectors.

Types of Aluminium Extrusion Profiles

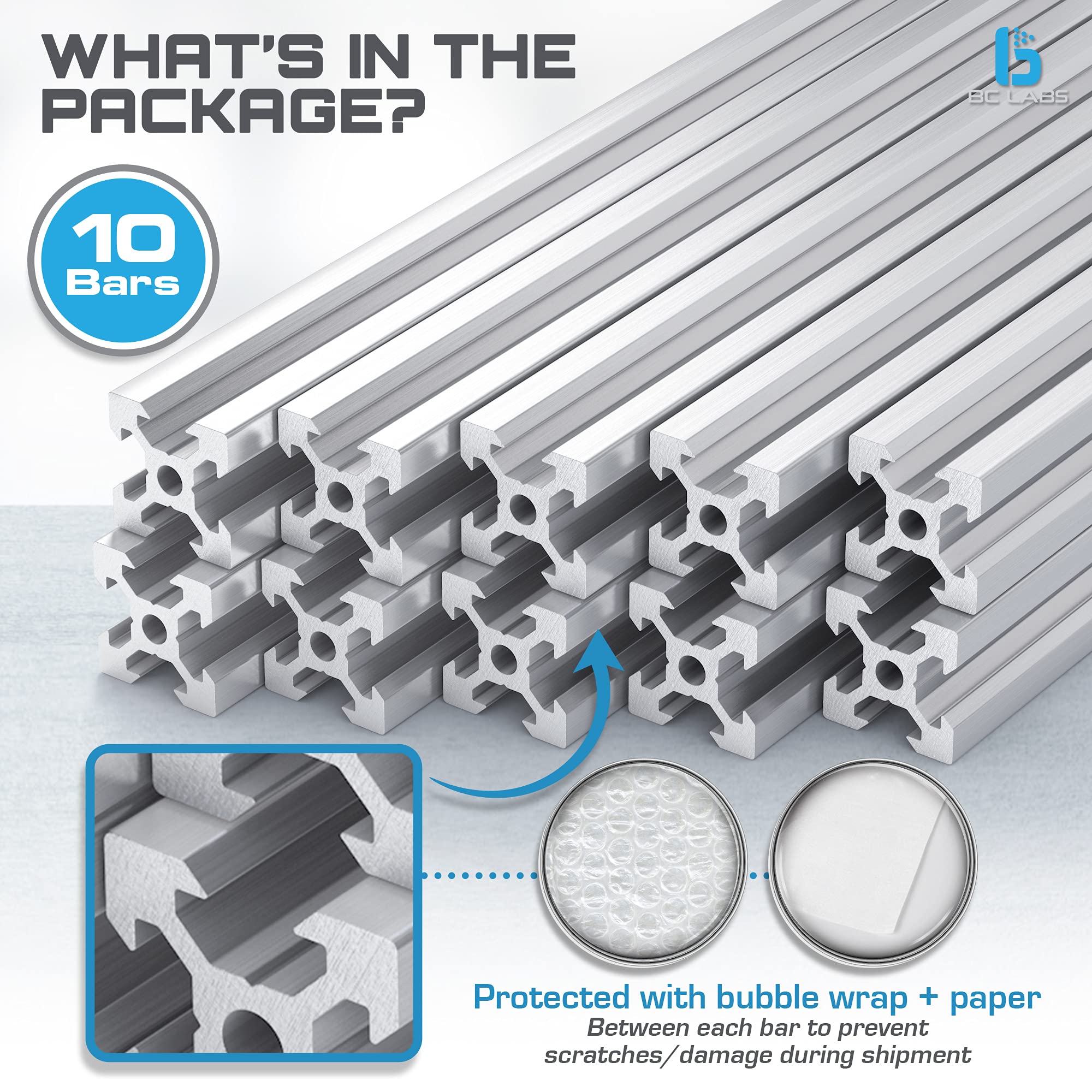

There are several types of aluminium extrusion profiles, including: * Standard profiles: These are pre-designed profiles that are available in a range of shapes and sizes. * Custom profiles: These are designed and manufactured to meet the specific needs of a customer. * Special profiles: These are designed for specific applications, such as high-strength or high-temperature applications.

Manufacturing Process

The manufacturing process for aluminium extrusion profiles involves several steps, including: * Design: The design of the profile is created using computer-aided design (CAD) software. * Tooling: The tooling for the extrusion process is created, including the die and any other necessary components. * Extrusion: The aluminium alloy is heated and pushed through the die to create the desired shape and profile. * Finishing: The extruded profile is then finished, which may include cutting, drilling, and other processes.

📝 Note: The manufacturing process for aluminium extrusion profiles can vary depending on the specific application and requirements of the customer.

Table of Aluminium Extrusion Profile Properties

| Property | Value |

|---|---|

| Density | 2.7 g/cm³ |

| Strength | up to 600 MPa |

| Corrosion resistance | good |

| Electrical conductivity | good |

Aluminium extrusion profiles are a versatile and widely used product, with a range of benefits and applications. By understanding the properties and manufacturing process of these profiles, customers can make informed decisions about their use in a variety of industries and applications.

The key points to take away from this discussion are the benefits and applications of aluminium extrusion profiles, as well as the manufacturing process and properties of these profiles. By considering these factors, customers can choose the right aluminium extrusion profile for their specific needs and requirements.

What are aluminium extrusion profiles?

+

Aluminium extrusion profiles are a type of product that is created through the extrusion process, where aluminium alloy is pushed through a die to create a specific shape and profile.

What are the benefits of using aluminium extrusion profiles?

+

The benefits of using aluminium extrusion profiles include corrosion resistance, high strength-to-weight ratio, good electrical conductivity, and recyclability.

What are the applications of aluminium extrusion profiles?

+

Aluminium extrusion profiles are used in a wide range of applications, including construction, transportation, industrial manufacturing, and electrical applications.