12 Atlantic Manufacturing Tips: Boost Productivity Now

Introduction to Atlantic Manufacturing

In the competitive world of manufacturing, staying ahead of the curve is crucial for success. Atlantic manufacturing, like many other industries, faces unique challenges that can impact productivity and efficiency. To boost productivity, manufacturers must adopt strategies that enhance their operations, improve quality, and reduce costs. In this article, we will explore 12 Atlantic manufacturing tips that can help manufacturers achieve their goals and stay competitive in the market.

Understanding the Challenges

Before diving into the tips, it’s essential to understand the challenges faced by Atlantic manufacturers. These challenges include: * Supply chain disruptions: Delays in receiving raw materials or components can halt production and impact delivery times. * Skilled labor shortages: Finding and retaining skilled workers can be difficult, especially in industries with specialized requirements. * Quality control: Ensuring high-quality products while meeting production deadlines can be a challenge. * Regulatory compliance: Staying up-to-date with changing regulations and laws can be time-consuming and costly.

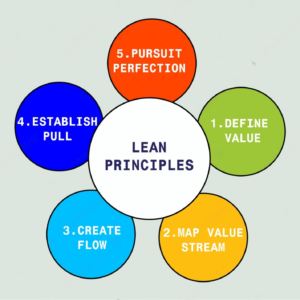

Tip 1: Implement Lean Manufacturing

Lean manufacturing is a philosophy that aims to minimize waste and maximize value-added activities. By implementing lean principles, manufacturers can: * Reduce waste and improve efficiency * Improve product quality * Increase customer satisfaction * Enhance employee engagement

Tip 2: Invest in Technology

Technology can play a significant role in improving productivity and efficiency. Some examples of technology that can benefit Atlantic manufacturers include: * Automation: Automating repetitive tasks can free up staff to focus on higher-value activities. * IoT devices: Internet of Things (IoT) devices can provide real-time data and insights to inform decision-making. * ERP systems: Enterprise Resource Planning (ERP) systems can help manage operations, track inventory, and optimize supply chains.

Tip 3: Develop a Skilled Workforce

Having a skilled and trained workforce is essential for productivity and efficiency. Manufacturers can: * Provide ongoing training and development opportunities * Offer competitive salaries and benefits * Encourage employee engagement and participation in decision-making

Tip 4: Enhance Quality Control

Quality control is critical in manufacturing, and manufacturers can take several steps to enhance quality, including: * Implementing quality control checks throughout the production process * Conducting regular audits to identify areas for improvement * Providing training on quality control procedures

Tip 5: Optimize Supply Chains

Supply chain optimization can help manufacturers reduce costs, improve delivery times, and increase efficiency. Some strategies for optimizing supply chains include: * Diversifying suppliers to reduce dependence on a single supplier * Implementing just-in-time inventory management to reduce inventory costs * Using data analytics to forecast demand and optimize production

Tip 6: Focus on Customer Satisfaction

Customer satisfaction is critical in manufacturing, and manufacturers can take several steps to improve customer satisfaction, including: * Conducting customer surveys to understand customer needs and preferences * Providing excellent customer service through multiple channels * Offering customized products to meet specific customer needs

Tip 7: Implement Sustainable Practices

Sustainability is becoming increasingly important in manufacturing, and manufacturers can take several steps to reduce their environmental impact, including: * Reducing energy consumption through energy-efficient equipment and practices * Implementing recycling programs to reduce waste * Using sustainable materials in production

Tip 8: Improve Communication

Effective communication is critical in manufacturing, and manufacturers can take several steps to improve communication, including: * Implementing regular team meetings to discuss progress and challenges * Using collaboration tools to facilitate communication and coordination * Providing clear instructions and training to ensure that employees understand their roles and responsibilities

Tip 9: Monitor and Analyze Performance

Monitoring and analyzing performance is critical in manufacturing, and manufacturers can take several steps to monitor and analyze performance, including: * Tracking key performance indicators (KPIs) such as productivity, quality, and delivery times * Conducting regular audits to identify areas for improvement * Using data analytics to inform decision-makingTip 10: Foster a Culture of Innovation

Innovation is critical in manufacturing, and manufacturers can take several steps to foster a culture of innovation, including: * Encouraging employee participation in decision-making and idea generation * Providing resources and support for research and development * Recognizing and rewarding innovative ideas and solutionsTip 11: Develop Strategic Partnerships

Strategic partnerships can help manufacturers access new markets, technologies, and expertise. Some strategies for developing strategic partnerships include: * Identifying potential partners that align with business goals and objectives * Building relationships with potential partners through regular communication and collaboration * Negotiating partnerships that benefit both partiesTip 12: Stay Up-to-Date with Industry Trends

Staying up-to-date with industry trends and developments is critical in manufacturing, and manufacturers can take several steps to stay informed, including: * Attending industry conferences and events * Participating in industry associations and networking groups * Subscribing to industry publications and newsletters💡 Note: Implementing these tips requires a commitment to ongoing improvement and a willingness to adapt to changing circumstances and industry trends.

To summarize, the 12 Atlantic manufacturing tips outlined in this article can help manufacturers boost productivity, improve efficiency, and stay competitive in the market. By implementing lean manufacturing, investing in technology, developing a skilled workforce, and focusing on customer satisfaction, manufacturers can achieve their goals and succeed in the industry.

What is lean manufacturing, and how can it benefit my business?

+

Lean manufacturing is a philosophy that aims to minimize waste and maximize value-added activities. By implementing lean principles, manufacturers can reduce waste, improve efficiency, and increase customer satisfaction.

How can I develop a skilled workforce in my manufacturing business?

+

Developing a skilled workforce requires providing ongoing training and development opportunities, offering competitive salaries and benefits, and encouraging employee engagement and participation in decision-making.

What are some strategies for optimizing supply chains in manufacturing?

+

Some strategies for optimizing supply chains include diversifying suppliers, implementing just-in-time inventory management, and using data analytics to forecast demand and optimize production.