10 Pro Tips To Generate Perfect Big Allen Wrench Now

Introduction to Big Allen Wrench

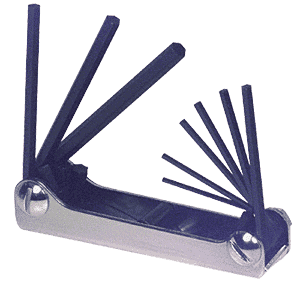

The Big Allen Wrench, also known as the allen wrench or hex key, is a versatile tool used for various applications, including construction, automotive repair, and industrial maintenance. Its unique hexagonal shape allows it to fit perfectly into corresponding bolts and screws, providing a secure grip and maximum torque. In this article, we will explore 10 pro tips to generate the perfect Big Allen Wrench.

Understanding the Importance of Big Allen Wrench

Before we dive into the tips, it’s essential to understand the significance of the Big Allen Wrench. This tool is indispensable in many industries, as it provides a reliable and efficient way to tighten or loosen hexagonal bolts and screws. The Big Allen Wrench is available in various sizes, ranging from small to large, to accommodate different applications.

Tip 1: Choose the Right Material

When generating a Big Allen Wrench, it’s crucial to select the right material. The most common materials used are steel, aluminum, and brass. Steel is the most popular choice due to its strength and durability. However, aluminum and brass are also suitable options for specific applications.

Tip 2: Consider the Size and Shape

The size and shape of the Big Allen Wrench are critical factors to consider. The hexagonal shape must be precise to ensure a secure fit into the corresponding bolt or screw. The size of the wrench will depend on the specific application, so it’s essential to choose the correct size to avoid stripping or damaging the bolt or screw.

Tip 3: Use the Correct Manufacturing Process

The manufacturing process used to generate the Big Allen Wrench can significantly impact its quality and performance. The most common methods include forging, casting, and machining. Forging is the preferred method, as it produces a stronger and more durable wrench.

Tip 4: Apply the Right Finish

The finish applied to the Big Allen Wrench can enhance its performance and durability. Common finishes include chrome plating, nickel plating, and powder coating. Chrome plating is a popular choice, as it provides a corrosion-resistant and wear-resistant surface.

Tip 5: Inspect the Wrench

Before using the Big Allen Wrench, it’s essential to inspect it for any defects or imperfections. Check the hexagonal shape for accuracy, and ensure the surface is free from scratches or blemishes.

Tip 6: Store the Wrench Properly

Proper storage of the Big Allen Wrench is crucial to maintain its quality and performance. Store the wrench in a dry and cool place, away from direct sunlight and moisture.

Tip 7: Use the Wrench Correctly

Using the Big Allen Wrench correctly is vital to avoid damaging the bolt or screw. Always use the correct size wrench, and apply gentle pressure to avoid stripping the threads.

Tip 8: Maintain the Wrench

Regular maintenance of the Big Allen Wrench is essential to extend its lifespan. Clean the wrench regularly, and apply a rust-inhibiting coating to prevent corrosion.

Tip 9: Consider the Ergonomics

The ergonomics of the Big Allen Wrench are crucial to ensure comfort and efficiency during use. The handle should be comfortable to grip, and the wrench should be balanced to reduce fatigue.Tip 10: Choose a Reputable Manufacturer

Finally, it’s essential to choose a reputable manufacturer when generating a Big Allen Wrench. A reputable manufacturer will ensure the wrench is made from high-quality materials and is manufactured using precise techniques.💡 Note: Always follow the manufacturer's instructions for use and maintenance to ensure the Big Allen Wrench performs optimally.

The Big Allen Wrench is a vital tool in many industries, and generating the perfect wrench requires careful consideration of various factors. By following these 10 pro tips, you can ensure your Big Allen Wrench is of the highest quality and performs optimally.

In terms of the benefits and drawbacks of using a Big Allen Wrench, the following table summarizes the key points:

| Benefits | Drawbacks |

|---|---|

| High torque and leverage | Potential for stripping or damaging bolts and screws |

| Durable and long-lasting | May require frequent maintenance |

| Versatile and adaptable | Can be heavy and cumbersome |

In summary, the Big Allen Wrench is a powerful and versatile tool that offers numerous benefits, including high torque and leverage, durability, and adaptability. However, it also has some drawbacks, such as the potential for stripping or damaging bolts and screws, requiring frequent maintenance, and being heavy and cumbersome.

To get the most out of your Big Allen Wrench, it’s essential to use it correctly, maintain it regularly, and store it properly. By following these tips and considering the benefits and drawbacks of using a Big Allen Wrench, you can ensure your tool performs optimally and lasts for a long time.

What is the most common material used to make a Big Allen Wrench?

+

The most common material used to make a Big Allen Wrench is steel, due to its strength and durability.

How do I store my Big Allen Wrench to maintain its quality and performance?

+

To store your Big Allen Wrench, keep it in a dry and cool place, away from direct sunlight and moisture.

What are the benefits of using a Big Allen Wrench?

+

The benefits of using a Big Allen Wrench include high torque and leverage, durability, and adaptability, making it a versatile and powerful tool.